Australian meat is highly regarded in both local and global markets for being top quality, wholesome and safe. The Australian Meat Processing (AMP) Training Package includes coverage of all the skilled job functions of the industry, including the essential foundation skills that are used daily. It is important the training package supports the workforce to learn skills and carry out work efficiently and safely. This will help Australian meat products live up to their strong reputation, operating to the current standards in food safety, quality control and compliance requirements.

Click across the tabs to view active and completed project stages. Consultation takes place at every stage of the project.

The AMP Training Package is undergoing a full review to meet both the Standards for Training Packages and the evolving needs of the industry. This project is the second stage of a broader project to review the entire AMP Training Package, and will focus on the essential skills in the Certificate II level qualifications, which support accredited training pathways for new entrants. The meat industry offers many rewarding career opportunities, with the potential to develop skills in biosecurity, sustainability, management and working with automated and robotic systems. It is important these qualifications reflect current industry and training delivery needs, including the role they can have in supporting the attraction and development of new learners.

This Skills Insight JSC project is being managed with the support of MINTRAC as part of their collaborative partnership with Skills Insight. MINTRAC has a strong history working with the Australian meat processing industry on skills and training solutions and have been engaged by Skills Insight to deliver this project in partnership.

Subscribe for updates

If you would like to receive updates about this project, please subscribe to our newsletter and select ‘meat processing’ as one of your industries of interest.

Project scope and purpose

This project will review the three Certificate II qualifications and units of competency, in particular reviewing the core units in these qualifications.

The following issues have already been identified during Stage 1 of the full review and apply to this second stage. Additional changes may be required based on stakeholder feedback received throughout the duration of this project.

Relevant occupations

Essential meat processing skills are used by everyone in the meat industry. The skills to prepare quality meat products hygienically and safely are utilised throughout a successful career in the industry. The ability to trim, bone and slice, package and arrange products for supply and apply portion control in abattoirs, retail or food service environments are some of the essential skills to be obtained through the Certificate II qualifications. If you are a meat processing employer or employee, we would like to hear from you.

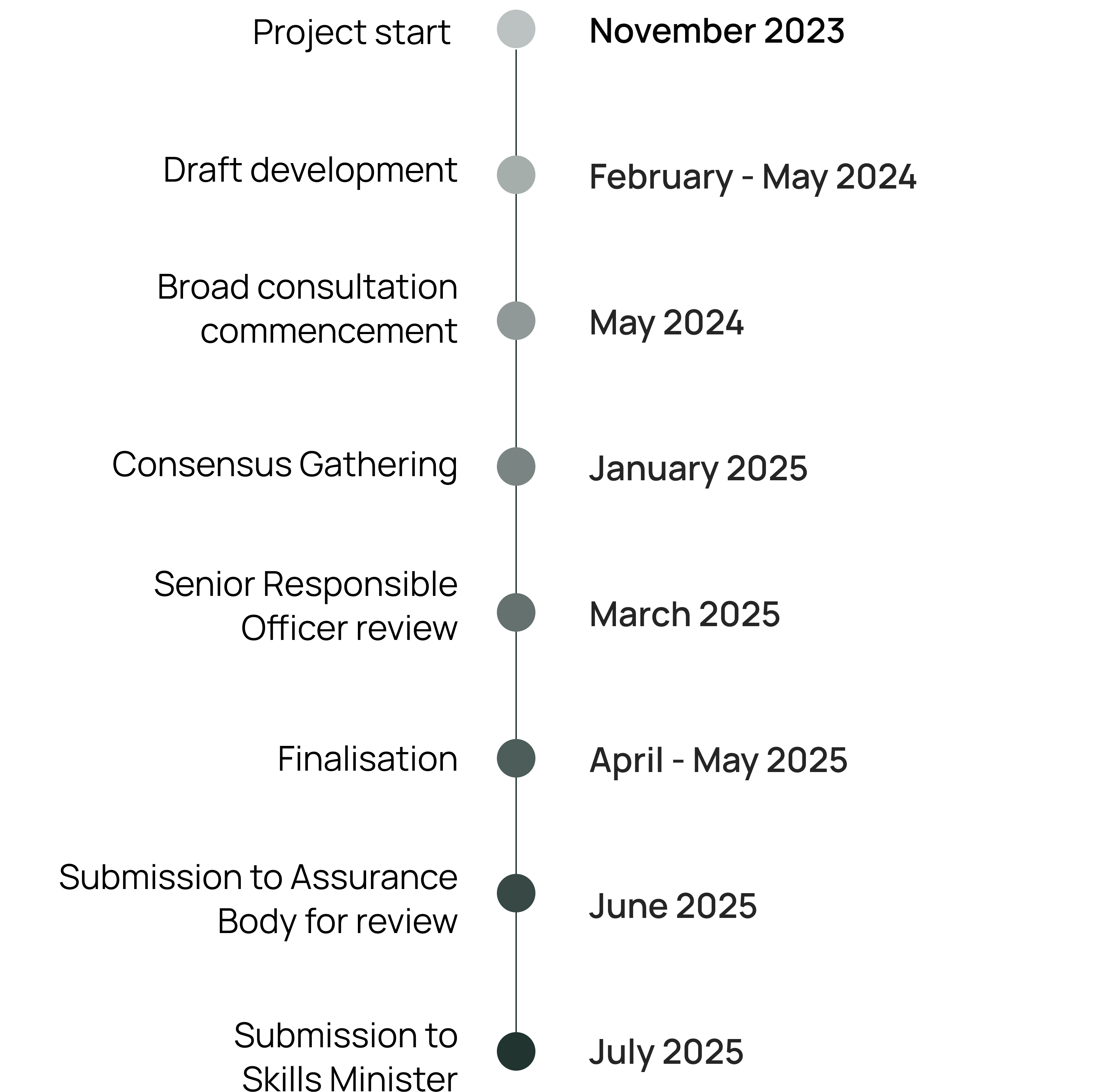

Timeline

Project team

Rebecca Ford

Project Manager

Skills Insight

[email protected]

Mark Wadsworth

Stakeholder Engagement Manager/Project Manager

MINTRAC

[email protected]

Lucinda O’Brien

Portfolio Manager

Skills Insight

[email protected]

Jenni Oldfield

Industry Skills Standards Contractor

Skill sets and units of competency to be reviewed

Below is a list of the qualifications and units of competency that will be reviewed. We welcome any initial feedback you have which will help us in the review and development process. In particular, any feedback you have about the 47 units and 2 skill sets that have been flagged for deletion due to fewer than 20 enrolments in the period from 2019-22. We are seeking feedback from workers in the meat processing industry, to hear if those using the Certificate II qualifications have any comments about the need for the inclusion of these units so that all relevant information has been considered before updates are made.

Please email any feedback or comments to [email protected]

Opportunities for stakeholder input

Stakeholder input is appreciated throughout the duration of this project. The documents will be drafted in consultation with the Technical Committee and their networks. Opportunities to provide targeted feedback will occur when the draft materials are made available in May, and again to review and check final drafts in January – February 2025. However, your feedback is welcomed at any time, and will help us in drafting the qualifications, skill sets and units.

A list of key stakeholder organisations has been created for this project, which Skills Insight and MINTRAC will contact to seek involvement and views on the draft qualifications, skill sets and units. Consultation is not limited to the organisations on this list. This list simply helps us to identify those organisations that, because of their industry role, size or specialty, are likely to have a key interest in the development and outcomes of this project. If you are aware of an organisation that you think should be involved, please contact the project team.

For updates and consultation opportunities, please subscribe to news and updates.

This project is part of the Annual Training Product Development Plan 2023-24.

Entrants to Australia’s meat processing industry require foundational skills to prepare quality meat products hygienically and safely. Work is underway to update the Certificate II level meat processing qualifications, which support accredited training pathways for new entrants. A Technical Committee has been established to provide advice throughout the project.

The Technical Committee had its first meeting on Wednesday 20 March with discussions focusing on enrolment data, job outcomes, foundation skills such as literacy and oral communication, and the Certificate II qualification core structure. The committee considered opportunities for new unit sectors, unit merges or deletions and if other units of competency could be suitable for inclusion in the AMP qualifications. They also discussed the possible merger of the Certificate II qualifications into a general entry level qualification that allows for pathways into a range of different job sectors.

Subscribe for updates

If you would like to receive updates about this project, please subscribe to our newsletter and select ‘meat processing’ as one of your industries of interest.

Development outcomes and next steps

The draft qualifications and units of competency will be made available on this webpage for broad stakeholder consultation and feedback in mid-May 2024.

The project team are continuing conversations with the Technical Committee and other industry stakeholders to gather additional knowledge to support updates to the qualifications and units of competency. Some key updates to the units that have been discussed include:

Following discussion with the Technical Committee and feedback received from stakeholders, the initial list of units of competency proposed for deletion is being revised and reduced, whilst still ensuring any duplicated skills are consolidated. Units covering job tasks that are rarely used or which are specialised or niche are being retained and updated. One example is job tasks that are rarely used but are essential to biosecurity and other risks including the skills to respond to an outbreak of diseases, such as mad cow.

Your input is welcome, please feel free to register your interest to keep informed of project updates and when draft materials are available for feedback.

Register for a consultation workshop

In-person and online workshops are planned for June & July to coincide with the draft documents being made available for broad stakeholder feedback. These sessions will provide further information about the work underway and how you can have input on the updated draft qualifications, skill sets and units of competency.

Register for a session that best suits you.

*An additional online session has been added for Wednesday 31 July (see below).

In-person sessions

Online Sessions

Currently there are three Certificate II level meat processing qualifications that support accredited training pathways for new entrants. The project Technical Committee, including subject matter experts, have reviewed the qualifications and supporting units of competency and skill sets to determine how they can best support the attraction and development of new learners. The Technical Committee have provided advice on the content and supported a review process to produce revised drafts that better reflect current industry and training delivery needs.

Thank you to everyone who provided feedback on the draft qualifications, skill sets and units of competency that were available for feedback between 15 May to 19 August 2024, as well as the additional drafts that were available from 1 October to 10 November 2024.

The project team has reviewed all feedback from stakeholders to guide further adjustments to the drafts, which are being considered by the Technical Committee. The documents will be made available for comment again at the consensus gathering stage in early 2025. During this stage we check our work with stakeholders to confirm the drafts are in line with expectations and seek final stakeholder feedback.

Subscribe for updates

If you would like to receive updates about this project, please subscribe to our newsletter and select ‘meat processing’ as one of your industries of interest.

Register for an Online Consensus Gathering Workshop

Online workshops are being held to discuss the most recent updates to the drafts and how to provide feedback. Please register for the time that best suits you. All times are AEDT.

Feedback collected from 1 October – 10 November 2024

Based on stakeholder feedback, it was determined that a selection of documents required further discussion before progressing to the ‘Consensus Gathering’ stage. These were available for feedback from 1 October to 10 November.

Feedback on teach out periods for the qualifications was also collected from Registered Training Organisations via an online survey.

The documents available during this period included:

- some units initially proposed for deletion that are now being retained and updated

- qualifications and units previously proposed for merging that are being retained to stand alone, including the Certificate II in Meat Retailing

- units included in the core of the draft qualifications

- additional units of competency to be housed in the meat retailing qualification

- three skill sets requiring additional updates

- poultry units, as consultation was affected during the previous consultation round due to avian flu impacting the industry

- any units that did not receive feedback during first round consultation.

The majority of units that make up this project are undergoing updates that did not require additional discussion at this stage. These units will be available again for comment in the Consensus Gathering stage, at which point you will have the opportunity to provide further input.

Two additional units added

Based on discussions during online workshops, two more units were added to this round of consultation.

Stakeholders supported the inclusion of AMPCLE2X04 Clean amenities and grounds in the Certificate II in Meat Processing to support important skills for keeping meat processing spaces hygienic.

Previous feedback on AMPA2060 Grade carcase indicated that carcass grading skills were not appropriate for use in the Certificate II of Meat Processing, so the unit was adjusted to AMPCRP2X20 Sort carcases to reflect the skills needed at this level. Feedback during the workshops indicated that there is still a need for grading skills to be captured in a higher level unit, so the draft unit AMPCRP3X02 Grade carcase was developed for inclusion in the Certificate III in Meat Processing.

Revised versions of the Certificate II and III in Meat Processing will be available again for review at the Consensus Gathering stage.

Online consultation workshops

Thank you to everyone who attended the online consultation workshops that were run as part of this round of consultation.

- Wed, Oct 2, 1-4 PM AEST (Meat retailing session)

- Tue, Oct 8, 2-5 PM AEDT (General session)

- Thu, Oct 10, 1-4 PM AEDT (General session)

View the documents

Feedback collected from 15 May – 19 August 2024

Summary of changes

Qualifications

The three Certificate II level meat processing qualifications were proposed to be merged together to become one qualification. The revised Certificate II in Meat Processing offers greater flexibility, with the ability to choose from a range of electives, without being restricted to one specialist area.

Units of Competency

One hundred and fifty-nine units of competency were reviewed, with new unit sectors proposed to help better identify the industry sector each unit affiliates with. Many units in the meat processing industry contain assessment components that must be completed in a workplace and cannot be achieved in a simulated environment. Feedback was encouraged on these Mandatory Workplace Requirements for each unit where it applies. Where possible, units covering similar skills and knowledge were merged or suggested to be replaced with other units to reduce duplication. This resulted in six units proposed for deletion. Some of these units duplicated the skills of another unit, with some others outlining skills that may no longer align with the current requirements of industry.

Skill Sets

Skills sets that contain some of the revised units and/or other units that were removed or updated as part of this project or other project work were also available for review.

For a detailed list of changes, please see the Summary of Changes document.

Consultation Workshops

In-person and online workshops were held in June and July to coincide with the draft documents being made available for broad stakeholder feedback. These sessions provided further information about the work underway and how stakeholders could have input on the updated draft qualifications, skill sets and units.

In-person sessions

Online Sessions

View the documents

Click on the accordions below to view the qualification and units of competency.

Summary of consultation to date

The draft qualification, skill sets and units were drafted in consultation with the Technical Committee and people working directly in meat processing who provided input on the skills and knowledge required for job roles and tasks. Units of competency that were initially proposed for deletion were available for feedback on this project webpage, under the Development tab, and have been reviewed with feedback requesting the majority be retained. Twelve site visits were undertaken to meat processing and meat retailing workplaces across Australia to observe these job roles in action.

During the initial Broad Consultation stage, feedback was collected via the Skills Insight Feedback Hub, email, and phone. In addition, we hosted eight face-to-face and three online workshops, which were attended by over 100 industry experts.

Thank you to those who have contributed to the project to date.

If you need to contact the project team, contact details are available on the ‘project plan’ tab.

To support accredited training pathways for new entrants, drafts of three qualifications, 11 skill sets and 152 units of competency have been updated based on stakeholder feedback. The project team has considered feedback from the Broad Consultation stage to revise the draft documents in consultation with the Technical Committee. The revised final drafts are now ready for review.

Thank you to everyone who provided comment and validation of the final draft qualifications, skills sets and units of competency that were available on this webpage from 4 February to 4 March 2025.

Feedback was sought on whether updates to the qualifications, skill sets, units and companion volume were accurate and appropriate. Feedback was also collected about the transition periods (previously teach out periods) for the qualifications via a survey below.

Subscribe for updates

If you would like to receive updates about this project, please subscribe to our newsletter and select ‘meat processing’ as one of your industries of interest.

Latest changes

Some of the latest key changes made after considering stakeholder feedback and consulting with the Technical Committee:

Online Consensus Gathering workshops

Online workshops were held to discuss the most recent updates to the drafts and how to provide feedback.

View the documents

Click on the accordions below to view the qualifications, skills sets and units of competency that were available for feedback.

Summary of consultation to date

The draft qualifications, skill sets, and units were developed in consultation with the Technical Committee, incorporating feedback from the first phase of Broad Consultation workshops conducted between May and August 2024. These workshops engaged stakeholders directly involved in meat processing and meat retailing, who contributed over 1,000 insights into the skills and knowledge required for various job roles and tasks. Eight face-to-face workshops, three online workshops, and twelve site visits to meat processing and retail workplaces across Australia provided valuable opportunities to observe these roles in action and gather detailed input from over 100 industry experts.

During the second phase of Broad Consultation, held from October 1 to November 10, 2024, a comprehensive review process continued. This phase sought input on two of the qualifications, three skill sets, and 50 units of competency. This phase included one online workshop focused on meat retailing, two online workshops for general meat processing, and one online workshop for poultry-specific feedback. A total of 72 stakeholders participated in these events, contributing valued comments and feedback. Further discussions with subject matter experts and the Technical Committee were conducted to collaborate with the project team in responding to stakeholder feedback received during broad consultation.

Thank you to those who provided feedback during these activities.

Contact the project team

Rebecca Ford

Project Manager

Skills Insight

[email protected]

Mark Wadsworth

Stakeholder Engagement Manager/Project Manager

MINTRAC

[email protected]

This project reviewed and updated the Certificate II level qualifications that support accredited training pathways for new entrants. The qualifications, along with related units of competency and skill sets, have been revised to reflect contemporary meat processing practices and evolving regulatory requirements. These updates are designed to ensure training outcomes align with real-world conditions, supporting improvements in productivity, quality assurance, and safety across the supply chain. This project was the second stage of a broader project to review the entire AMP Training Package, so that it can meet the Standards for Training Packages and support training and skills development that is relevant, practical, and aligned with current industry needs.

The final draft qualifications, units of competency and skill sets are currently undergoing proofreading, anti-discrimination assessment and quality checks. They are being reviewed to ensure they are of high quality and comply with the Standards for Training Packages 2022, the Training Package Products Policy and the Training Package Products Development and Endorsement Process Policy. This ensures that any barriers to training have been identified, acknowledged, addressed and reduced as far as possible, to enable people to gain the skills required to participate in the workforce and society.

Once these checks have been completed, the training products and Consultation Log will be sent to the Senior Responsible Officers for their consideration; seeking their support for submission to the Assurance Body.

A Companion Volume Implementation Guide is also being produced to assist industry and registered training providers (RTOs) deliver the units, qualifications and skill sets. It will include key information to help trainers adapt to upcoming changes, along with guidance on how regulatory updates, licensing requirements, and workplace health and safety considerations may affect their training.

Key outcomes

The skills required of workers who can thrive in an increasingly complex and competitive global market have been embedded into the revised qualifications, skill sets and units, to support industry to respond effectively to change, foster innovation, and maintain high standards in meat production and processing.

To support learners developing the skills and knowledge required to excel in the evolving meat processing industry, the following changes have been implemented:

Summary of Consultation

Thank you to everyone who volunteered their time and expertise throughout this project.

The draft qualifications, skill sets, and units were developed in consultation with the Technical Committee, incorporating feedback from the first phase of Broad Consultation workshops conducted between May and August 2024. These workshops engaged stakeholders directly involved in meat processing and meat retailing, who contributed over 1,000 insights into the skills and knowledge required for various job roles and tasks. Eight face-to-face workshops, three online workshops, and twelve site visits to meat processing and retail workplaces across Australia provided valuable opportunities to observe these roles in action and gather detailed input from over 100 industry experts.

During the second phase of Broad Consultation, held from October 1 to November 10, 2024, a comprehensive review process continued. This phase sought input on two of the qualifications, three skill sets, and 50 units of competency. This phase included one online workshop focused on meat retailing, two online workshops for general meat processing, and one online workshop for poultry-specific feedback. A total of 72 stakeholders participated in these events, contributing valued comments and feedback. Further discussions with subject matter experts and the Technical Committee were conducted to collaborate with the project team in responding to stakeholder feedback received during broad consultation.

‘It has been a privilege and an honour to have been actively involved throughout the project and provided feedback to help shape draft standards to align with current industry needs.‘ Roy Simpkin Group Workplace Trainer and Assessor, JBS Australia

Consultation during consensus gathering stage

‘One aspect of particular interest to me is the merger of Certificate II qualifications, which allows for greater flexibility in training across different plants and sections. Additionally, retaining the Certificate II in Meat Retailing as a stand-alone qualification is crucial to cover the diverse skills and knowledge required in the retail sector.’ Warwick Bricknell, RTO Manager, CHM Alliance RTO

‘The Essential Meat Processing Skills Project has achieved several positive outcomes that align with current industry standards and expectations while also addressing the need for cost savings and reducing duplication.’ Douglas Jobson, CEO, Macro Group Australia

All feedback has been recorded and responded to in the Skills Insight database. Below you can view a summary of feedback from the ‘Broad Consultation’ stages and the ‘Consensus Gathering’ stage. You can also view a summary of changes made to the qualifications, skill sets and units of competency.

Documents

Click on the accordions below to view a list of the draft qualifications, skill sets and units of competency currently undergoing proofreading, anti-discrimination assessment and quality checks.

This Skills Insight JSC project is being managed with the support of MINTRAC as part of their collaborative partnership with Skills Insight. MINTRAC has a strong history working with the Australian meat processing industry on skills and training solutions and have been engaged by Skills Insight to deliver this project in partnership.

Project background

Australia’s meat processing workforce is made up of an estimated 54,000 people, who contribute $3.5bn annually to the Australian economy. The AMP Training Package went through a series of small changes between 2015 – 2020 to meet specific industry needs. While carrying out this work, it became apparent that the entire training package required a review to meet the updated priorities in the Training Package Development and Endorsement Process Policy and Training Package Standards.

A full review was proposed and is now being completed in several stages to minimise disruption to current apprenticeships and ongoing training and workforce development. Stage one, completed in 2022, focused on the qualifications, skills sets and units that describe general safety, quality assurance and leadership skills for meat processing, which included some of the Certificate III and IV qualifications. The next stage of this broader project will look at the remaining Certificate III qualifications and the accompanying units of competency and skill sets.

Some of the initiatives that are particularly important to the overall AMP Training Package review include:

We are taking an holistic approach to the review of the AMP Training Package to ensure that the training package products meet both the Standards for Training Packages and current industry needs.